About GLTAA

The history of glulam

The practice of gluing pieces of timber together, whether for decorative or functional purposes, has been with us for thousands of years. However, the concept of gluing relatively thin layers of timber together to form a structural member is a development of the twentieth century. These structural members are referred to as ‘glulam’.

Glulam Facts

Decorative Glulam

Decorative glulam is largely used in kitchen bench tops. Other common uses are bar tops, stair treads and stringers, kitchen cabinet doors, seats, coffee tables, etc.

Used decoratively, glulam does not require structural strength, but rather aesthetics, durability, and hardness. The quality of the finish is of paramount importance, as the product is visible at all times and the performance of the glulam is also of primary importance. The product must be stable and without defect.

The quality assurance system is intrinsic in achieving a consistent and reliable product and a number of the GLTAA members specialise in this product area.

Structural Glulam

Structural glulam for use in primary structural members in domestic, commercial, and industrial buildings is produced by most of the GLTAA members.

Depending on location, the timber species used in the manufacturing process differs from producer to producer. In the west, the predominant timber species is Jarrah, in the south east, Tasmanian Oak and Radiata Pine and in the north east, Spotted Gum, Slash Pine and other mixed hardwoods, such as Blackbutt, Iron Bark, Sydney Blue Gum, etc.

In the past, this widely varying resource has created difficulties in trying to standardise glulam as a structural product. The milling procedure differs from mill to mill, and from species to species and the result has been that each producer has manufactured glulam of differing mechanical properties and of differing depths and widths. Designers were unsure of which properties and sizes were compatible, available and economic and the variance caused them problems in designing glulam.

As a result, the glulam manufactured by the GLTAA members has now been rationalised in order to establish a set of industry standard properties and corresponding sizes. The table below shows the GLTAA Glulam Mechanical Properties.

The designation of each group relates to the short duration stiffness (in GPa). The standard section sizes relating to each mechanical property group are available on request from members. These section sizes are the finished sizes of the glulam supplied. It is important for designers to note, that the correct designation be nominated on drawings, e.g. 315×85 GL18.

This makes the suppliers, builders, checkers and inspectors aware that the beam is to be an accredited section of known size and grade. It allows all producers capable of producing the grade of glulam to price the project without the designer having to make the decision to specify a one supplier product. The designation noted may be followed with a timber species if the designer requires a specific appearance. It should also be followed with a `C’ for cambered (600M Industry Standard Radius) or an `S’ for straight beams.

Producers nominated in their accreditation procedures which glulam properties they produce. The make up of the glulam may be in any configuration, so long as the grade and size of the glulam match that designated.

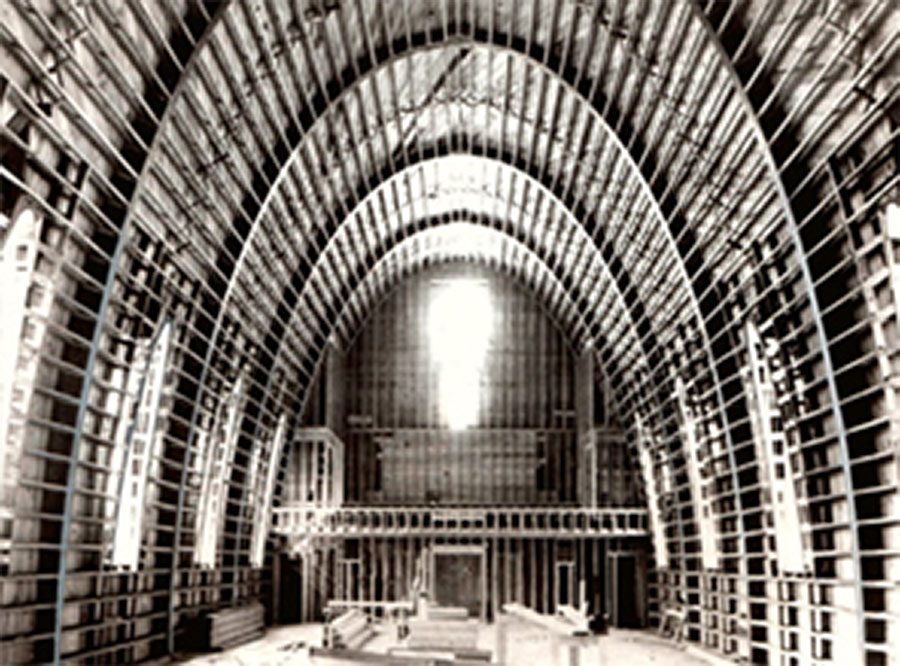

Some Glulam

Projects

These are some of the latest developments using our products. All of these constructions have been submitted from our members.

ENVIRONMENTAL CREDENTIALS

Natural Structural Material

Sustainable Principles

The long term resource security of timber as a structural material is assured with sound forestry management and adherence to sustainable development principles established in Australia and around the world.

Forest Resources

The management of multiple use forests carefully plans for the protection of habitats for plant and animal species, water catchments and soil quality.

Greenhouse Effect

As trees grow, photosynthesis results in the production of oxygen and the absorption of carbon dioxide, the major cause of the greenhouse effect. Carbon dioxide is removed from the atmosphere firstly by phytoplankton in the oceans and secondly by forest cover around the world.

Demand Increase

The global per capita consumption of timber is approximately 0.67 cubic metres per year, which has remained largely unchanged since 1960.

Value Adding

Glued laminated timber (glulam) is a valued added product which utilises short pieces of timber of relatively small size and joins them by gluing into large structural timber.

Energy Efficient

A structural timber member is 60% of the weight of a similar structural steel member, however the energy requirement of the latter can be as much as 40 times greater.

Independent Accreditation Process

- The GLTAA is associated with the CEMQA P/L who acts as the inspectorate for the GLTAA and carries out the qualification and on-going audit process leading to the certification of the QA system.

- CEMQA and Universal Testing Facility P/L (UTF) also act in a research capacity for the association.

- An Accredited Member may bear the GLTAA Trademark on their product and promotional materials signifying quality assured products

GLTAA Governance

- The GLTAA was formed in 1990 with the aim of developing a Quality System to be used as a minimum standard benchmark for all members when manufacturing Glulam products.

- The GLTAA is a not-for–profit organization which is structured as a Proprietary Limited Company with a limited liability of the shareholders, the producer and Importer members.

- GLTAA is actively involved in the formation and review process of Australian Timber Standards for the manufacture and design of glulam products.

- Glued Laminated Timber Association of Australia (GLTAA) Rules govern the association’s operations.